- Products

- Markets

- Applications

- Cigarette Paper Perforation

- Cigarette Perforation

- Laser Perforation

- Laser Microperforation

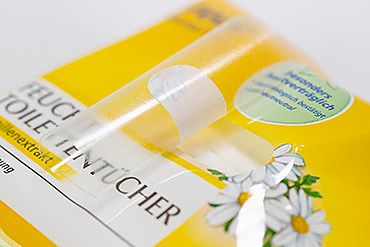

- Easy Open Packaging

- Modified Atmosphere Packaging

- Breathable Packaging

- Laser Scribing

- High-precision Safety Features

- Laser Smart Card Processing

- Lasermarking

- Abrasives Converting

- Laser cutting

- Laser cutting of foils

- Laser cutting paper

- Laser cutting metal foils

- Laser marking

- Service

- Company

-